|

| Revolutionizing Metal Recycling with ISSC Metal Scrap Shredding Line |

Revolutionizing Metal Recycling with ISSC Metal Scrap Shredding Line

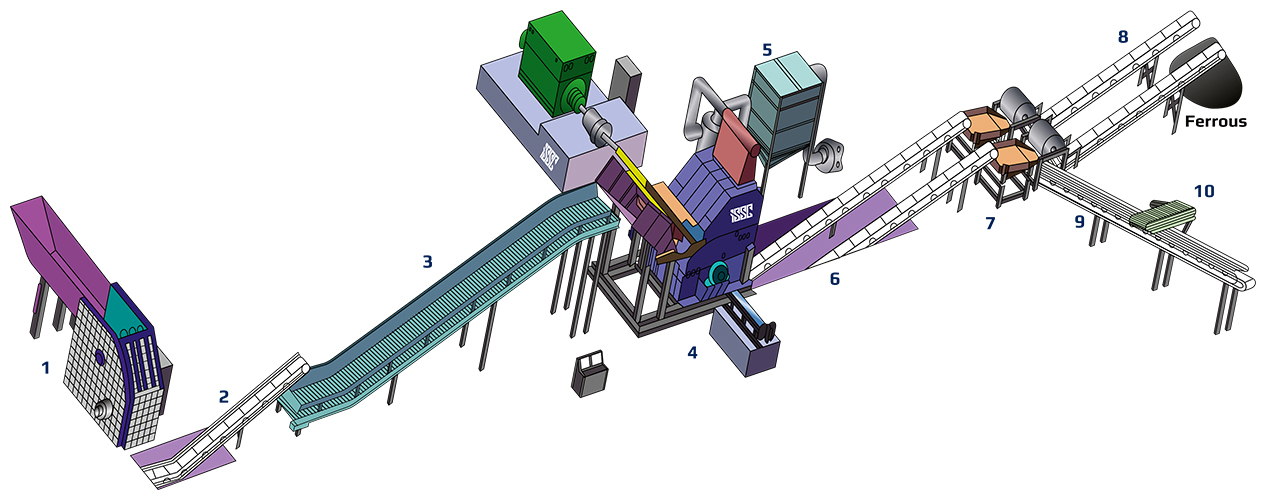

In today’s world, efficient waste management and recycling practices are more crucial than ever. The ISSC Metal Scrap Shredding Line is designed to meet these needs head-on, providing an innovative solution for metal recycling with advanced technology and unparalleled performance.

Key Features of the ISSC Metal Scrap Shredding Line

- Hammer Mill Shredder

The heart of our shredding line is the powerful hammer mill shredder. This machine excels at crushing and shredding various types of metal scrap into smaller, manageable sizes. Its high-speed operation ensures thorough processing, making it ideal for heavy-duty applications.

- Double Shaft Shredder

For larger and tougher materials, the double shaft shredder is the perfect choice. With its robust design and dual-shaft technology, this shredder provides consistent and efficient results, ensuring that even the most challenging scrap is handled with ease.

- Magnetic Separation

One of the standout features of our shredding line is the integrated magnetic separation system. This technology effectively separates ferrous metals from non-ferrous materials, significantly enhancing recovery rates. This means you can maximize the value of your scrap and reduce waste.

- Dust Removal System

Environmental responsibility is a priority at ISSC. Our dust removal system minimizes airborne particles during the shredding process, promoting a cleaner and safer working environment. This feature not only benefits your operations but also aligns with eco-friendly practices.

Why Choose ISSC?

At ISSC, we are committed to providing top-notch solutions that empower businesses in the metal recycling industry. Our shredding line is designed for versatility and efficiency, making it suitable for a wide range of applications. Whether you're a small scrap yard or a large industrial operation, our technology can help streamline your processes and boost productivity.

Conclusion

If you're looking to elevate your metal recycling operations, the ISSC Metal Scrap Shredding Line is your go-to solution. With its state-of-the-art hammer mill and double shaft shredders, magnetic separation, and dust removal capabilities, you can achieve optimal results while maintaining a commitment to sustainability.

For more information, visit us at www.isscindia.com or contact us today to discuss how we can assist you in transforming your recycling processes!

Let’s work together to create a cleaner, greener future through effective metal recycling! ♻️✨